- Developed in the 1980s

- Commercially available since the early 1990s

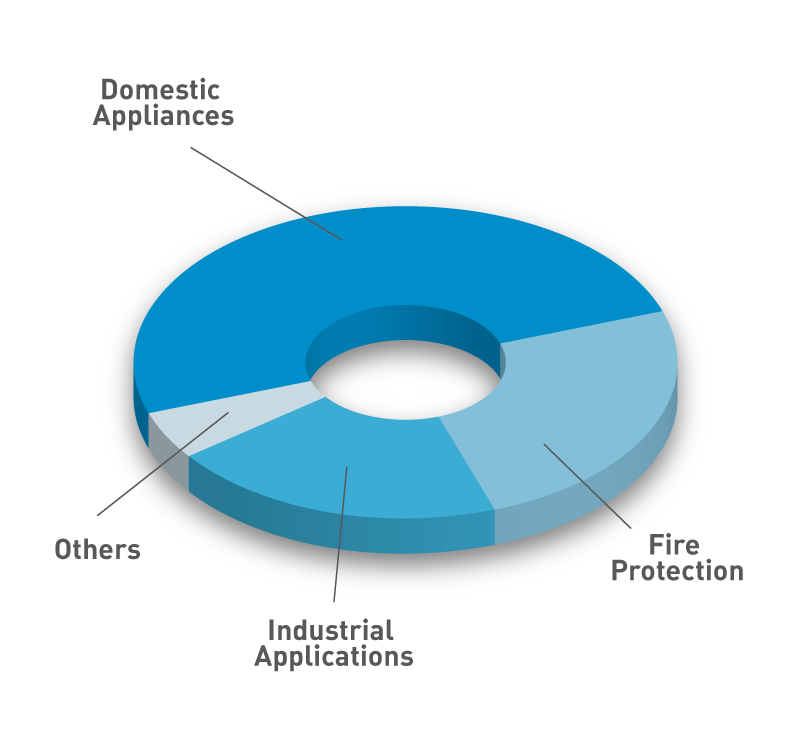

- Used in domestic appliances, fire protection and industrial applications

- Exonerated from Carcinogenic classification

- Low Biopersistence

- Can be used up to 1400 °C

Under Note Q, LBP wools must contain more than 18 weight-% alkali metal or alkaline earth oxides and meet requried low biopersistence criteria. The most commonly known example are AES wools, which consist of amorphous fibres produced by melting a combination of CaO-, MgO- and SiO2 (see also EN 1094-1; VDI-recommendation 3469, Parts 1 and 5). As the chemical composition of HTIW is a key factor not only for the technical performance but also for the regulatory status of the wools, manufacturers are in constant search of new LBP wools for high-temperature insulation.

Key features are:

- low thermal conductivity

- low biopersistence

- low linear shrinkage up to their use limit

Fibre properties can be adjusted by varying the quantity of alkali-metal or alkaline-earth for different application areas. The fibres are manufactured using high purity raw materials.

Products made from LBP wools are generally used at application temperatures > 600 °C in industrial equipment, fire protection, automotive exhaust systems and domestic appliances. Their use in applications has grown significantly since their commercial production began in the early 1990s.

Specific technical product information is available from your supplier.

LBP Wool Applications

Regulatory Classification Status

Following scientific assessment, LBP wools are exempt from classification. They fulfil the Exoneration Criteria of Note Q of the Classification, Labelling and Packaging Regulation (EC/1272/2008) based on biopersistence tests or long-term animal studies. (Annex VI part 3 table 3.1 of CLP, reference group EU index number 650-016-00-2.)

Under Note Q, LBP wools must contain more than 18 weight-% alkali metal or alkaline earth oxides and meet requried low biopersistence criteria. The most commonly known example are AES wools, which consist of amorphous fibres produced by melting a combination of CaO-, MgO- and SiO2 (see also EN 1094-1; VDI-recommendation 3469, Parts 1 and 5). As the chemical composition of HTIW is a key factor not only for the technical performance but also for the regulatory status of the wools, manufacturers are in constant search of new LBP wools for high-temperature insulation.

LBP & REACH

Regulation (EC) No 1907/2006 of the European Parliament and the Council of 18 December 2006 concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) requires manufacturers, importers and or the exclusive representative of non-European manufacturers to share data on potential health and environmental hazard and provide data to the European Chemicals Agency (ECHA) in a formalized registration process.

All LBP including AES are registered under REACH and can therefore be used in the European market.

Cartoon; Best working practices

A number of member states have national Occupational Exposure Limits for MMVF’s (including LBPs). Care should be taken to minimise generating workplace dust when handling any HTIW Product. More information can be found in the support section.

Further specific information can be found on your supplier’s SDS.

All relevant local, state, regional and national regulations should be observed at all times when using these products.